+91 88812 52752

Explore The Features

Our Products

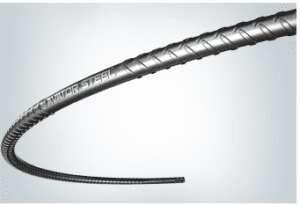

AVATOR 550D

The latest breakthrough in steel is here.

Introducing Avator 550D with Ultragrip Technology. It provides superior protection and strength, thereby helping in enhancing lifespan of constructions

Avator 550D Mechanical Properties

| Properties | BIS STD IS: 1786 Fe 550D | Avator Fe 550D |

|---|---|---|

| Yield Stress | 550 | 570 |

| Tensile Strength | 600 N/mm² | 660 N/mm² |

| % Elongation (min) | 14.5 | 18 |

| Properties | BIS STD IS: 1786 Fe 550D | Avator Fe 550D |

|---|---|---|

| % Carbon (C) (max) | 0.25 | 0.20 |

| % Sulphur (S)(max) | 0.040 | 0.030 |

| % Phosphorus (P) (max) | 0.040 | 0.040 |

| % S & P (max) | 0.075 | 0.075 |

Unparalleled Bond Strength

Avator 550D TMT Bars come with Ultragrip technology. The unique rib pattern adds to the grip power, which increases bond strength with concrete manifold when compared to ordinary TMT bars.

Superior Tensile Strength

Avator 550D TMT Bars are made with advanced German Thermex QST technology which increases the strength of the structures making it a natural choice for multistoried constructions.

Better Elongation and Weldability

Avator 550D TMT Bars have the right mix of chemicals which result in better elongation and weldability without compromising on strength

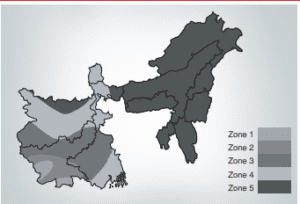

Superior Earthquake Resistance

Avator 550D TMT Bars have been created to provide superior protection from damages that can be caused by earthquakes. Hence it can be used in areas where the probability and occurrence of earthquakes are great as well as in other areas.

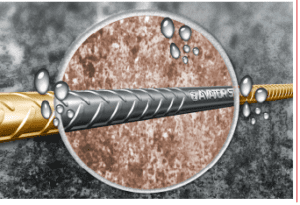

Advanced Corrosion Resistance

Avator 550D TMT Bars provide superior corrosion resistance from environmental oxygen and the water in the concrete thus protecting against rust and extending the life of constructions.

AVATOR RUSTGUARD

A specially researched product coming from one of the finest producers of steel in India, Avator RustGuard is a technological marvel specially created to provide complete protection against corrosion. It extends the life of the construction manifold while providing the best possible strength.

Avator RustGuard uses Fusion Bonded technology wherein a metaloplast membrane gets infused with the top molecular layer of the steel body making it chemically neutral to all normal acidic and basic conditions. Avator RustGuard TMT bars pass through various stages like surface preparation by shot blasting, heating of rebars upto 2400 C by induction heating, epoxy coating of rebars by electrostatic process, quenching of rebars and a host of testing on the finished product. Avator RustGuard conforms to BIS IS-13620:1993 standards.

High strength and ductility come from the fine grain multiphase composite structure. The metaloplast membrane leads to better stretchability and toughness. Since mechanical properties of the rebar remain unchanged, the inherent strength of the TMT is uncompromised. Neither the outer surface nor the inner surface is raptured during bending operations and high thermal stability is maintained. This leads to better weldability. Micron-level coating also results in excellent bendability.

| Properties | BIS STD IS: 1786 Fe 550D | Avator Fe 550D |

|---|---|---|

| Yield Stress | 550 | 570 |

| Tensile Strength | 600 N/mm² | 660 N/mm² |

| % Elongation (min) | 14.5 | 18 |

| Properties | BIS STD IS: 1786 Fe 550D | Avator Fe 550D |

|---|---|---|

| % Carbon (C) (max) | 0.25 | 0.20 |

| % Sulphur (S)(max) | 0.040 | 0.030 |

| % Phosphorus (P) (max) | 0.040 | 0.040 |

| % S & P (max) | 0.075 | 0.075 |

Rustguard Properties Comparison

| Parameter | IS 13620 : 1993 | Avator Rustguard |

|---|---|---|

| Bare Bar Properties | As per IS 1786: 2008 | Conforming to IS 1786: 2008 |

| Coating Thickness | 100 to 300 microns | 175 to 300 microns |

| Coating Holiday | 6 Holiday /m (max) | 5 Holiday /m (max) |

| Coating Flexibility | 120° Bend using 10D | 120° Bend using 8D & 10D complying |

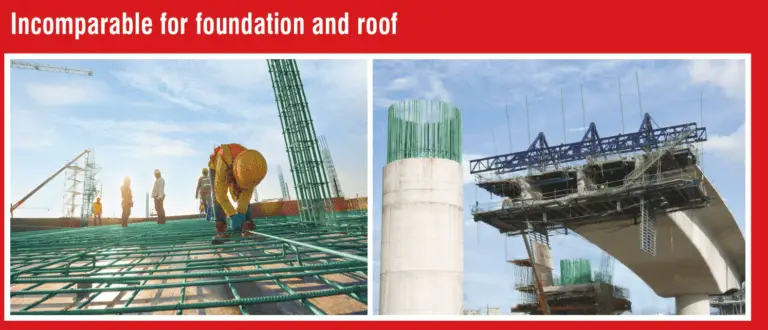

Extended Life of construction

Since Avator RustGuard completely cuts off environmental oxygen and water in concrete, corrosion becomes impossible as a result of which the life of constructions increases manifold. It extends the longevity of structures in harsh corrosive environments.

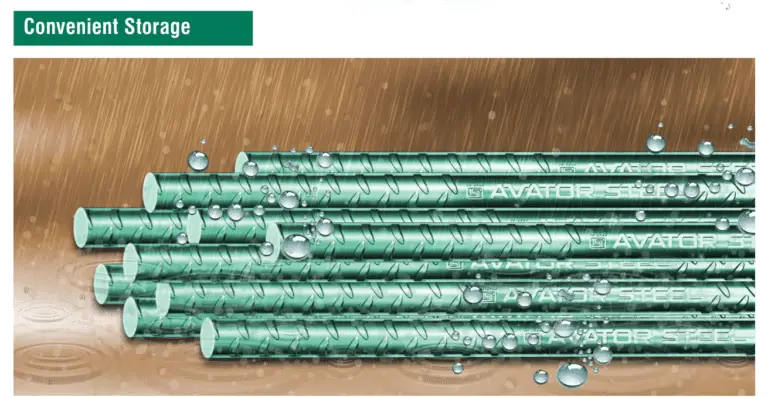

Avator Rustguard TMT bar is convenient to store. Oxidation of the rebar is prevented, and the bars remain completely corrosion free even during extended period of storage.

AVATOR RINGS

As a part of its commitment to innovate and add value, Avator Steel has also introduced ready to use Avator TMT Rings. These rings have been introduced with a focus on saving cost and time.

Made at the same plant where Avator TMT bars are produced, these TMT Rings help reduce the construction time significantly. They also help in checking wastage and go a long way towards saving labour cost.

AVATOR WIRE

Avator Wire is a superior quality wire which is convenient to use for tying TMT bars. These wires have the double advantage of being ductile and strong and have a uniform and consistent diameter. Avator wires offer a higher length per kg which ensures a higher number of tie-ups. Avator wires are securely tied up to keep quality intact.

AVATOR NAILS

Avator nails are manufactured and designed using quality raw materials as per quality standard norms. These nails are corrosion resistant, have high tensile strength, and highly durable. Stiff and strong properties make Avator Nails resistant to bending and they have strong holding power. Annular grooves on the nails and the large head (which is usually much larger and flatter than other types of nails) improves the holding capacity.

Seamless surface and perfect bite angle allow strong grip on working surface. Avator Nails have huge acceptance in the market for its superior quality and is widely used in the construction industry and carpentry work.

our Products

- AVATOR 550D

- AVATOR RUSTGUARD

- AVATOR RINGS

- AVATOR WIRE

- AVATOR NAILS

Useful Links

Contact Us

If you have any questions need help feel free to contact.

Phone: +91 88812 52752

Email Id: mohaneldudahi@gmail.com

Designed by Wizone